An extraordinary instrument requires extraordinary attention to detail. Specializing in the complete restoration of the world’s finest makes of grand and upright pianos, we put our expertise and attention to detail toward crafting instruments that satisfy the most demanding musicians.

Customized restorations

No two pianos are the same, and no two restorations should be either. At Philatuner, every restoration we do is tailored to enhance the qualities that make your piano unique and meaningful to you.

meticulous craft

While others are content to do the work merely well enough, at Philatuner we invest the time and energy in processes that produce truly great results, and no project is finished until it meets both our clients’ and our own exacting standards.

Exceptional Service

Excellent service extends beyond the technical aspects of the restoration to encompass the entirety of the customer experience. From start to finish, our client-centered approach is at the core of what we do.

Whether restoring a golden age Steinway with meticulous attention to detail or bringing a favorite instrument to better-than-new condition, our customized restoration plans bring out the best in every instrument.

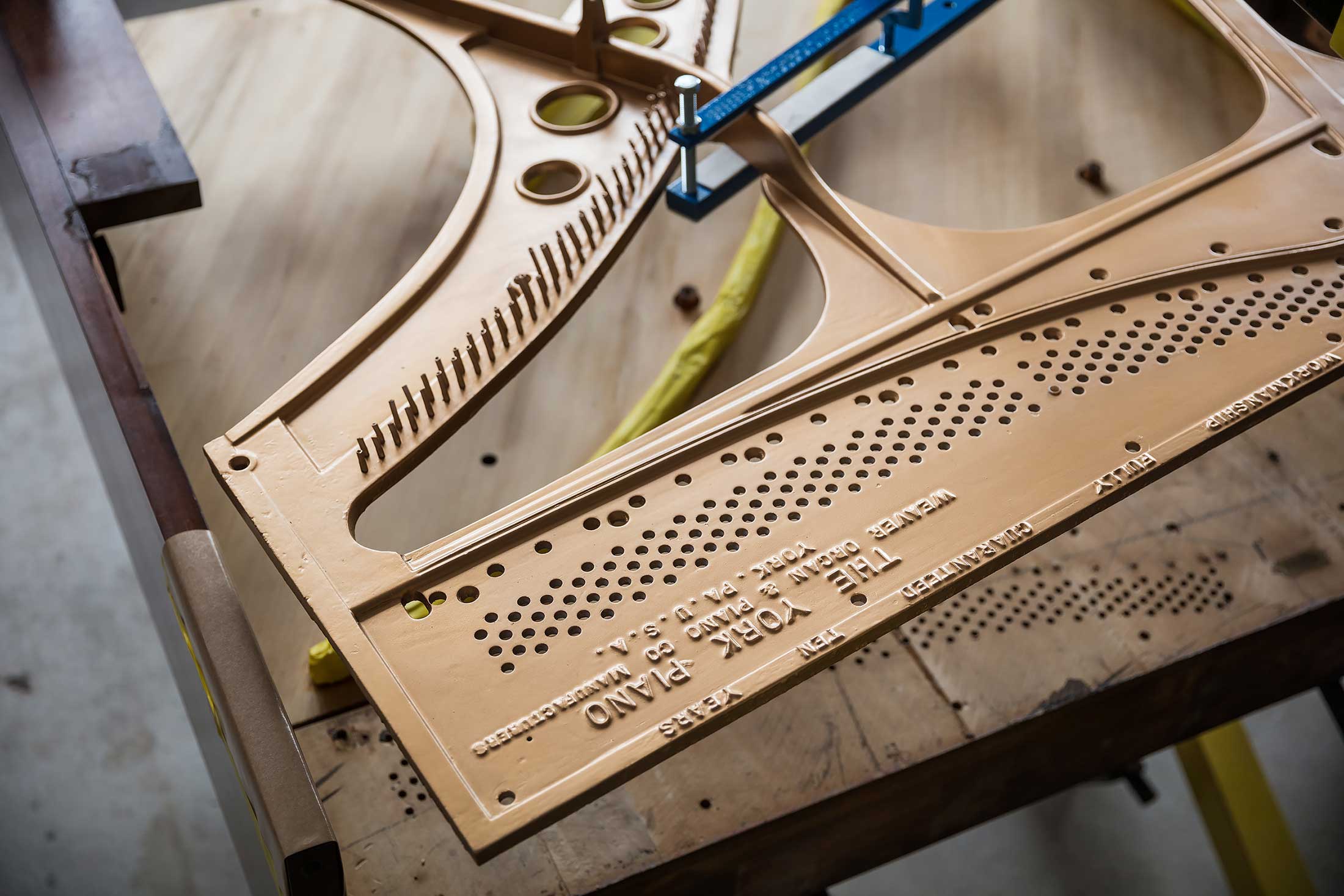

EVERY DETAIL MATTERS The final touch of a full rebuilding, the intricate lettering on the re-gilded cast iron plate is always lettered by hand.

01

REBUSHING Testing bushing cloth of different thicknesses to find a balance between tight tolerances and low friction.

reconditioning plan

In pianos with minor wear or when existing parts are in good condition, reconditioning will bring back the responsiveness and tonal richness inherent in the instrument’s original design.

restoration plan

When more work is needed than basic regulation but less than total rebuilding, our restoration plan serves as an effective middle ground for deeper work on select systems within a piano.

NEW KEYTOPS After precision-milling, the final touches to a set of restored keys are completed by hand.

02

RESTORING THE BELLY Restored pianos retain the original wood of the soundboard, pinblock, and bridge root.

03

BELLY RESTORATION After the soundboard is repaired and re-varnished, the re-gilded plate is lowered carefully back into the belly of the piano.

rebuilding plan

When the highest standards of performance and aesthetic are desired, complete rebuilding allows a piano to be faithfully returned to its original condition, resulting in an instrument that looks and feels like better than new.

REFINISHING Following the removal of the old finish and the dyeing and color-matching of the original wood, the case is refinished with a topcoat of the desired sheen.

compare our plans

action

case

belly

action

case

belly

action

case

belly

Tom completed a thorough reconditioning of our 110-year-old Steinway Vertegrand piano in his shop and at our house; its new and wonderful sound and exceptional action make it seem like it just emerged from the Steinway factory in 1909!”

– Steve Moore

LEFT After the restoration work is completed, the final product is inspected and prepped for delivery.

ABOVE After the restoration work is completed, the final product is inspected and prepped for delivery.

Our Process

Scroll to see full timeline →

Frequently asked questions

Tom turned back the clock on my piano, and he did it with calm assurance, professionalism, and real care. You don’t have to look any further: Tom Rudnitsky’s the piano-whisperer you’ve been waiting for.”

– Paul Saint-Amour

RIGHT Stripped to the bare sitka spruce panels, cracks are repaired with a proprietary synthetic wood, and the soundboard is re-varnished by hand.

ABOVE Stripped to the bare sitka spruce panels, cracks are repaired with a proprietary synthetic wood, and the soundboard is re-varnished by hand.

Ready to get started? Let's schedule a consultation.